You’ve probably heard of the term “digital twin” but aren’t sure what it means or how it can help your business. A digital twin is a virtual replica of a physical object or system. There are various different types of digital twins such as component, asset, system and process twins.

Digital twins have become an important part of Industry 4.0 and the Internet of Things (IoT). They allow companies to improve product quality, optimize operations and reduce costs. For example, Airbus uses digital twins to monitor the health of its aircraft engines in real time. This helps them to identify potential problems early and take preventative action.

In this blog post, we will discuss the different types of digital twins and their benefits. We will also provide examples of how businesses are using them to improve product quality and operations.

What is a digital twin & what are their benefits?

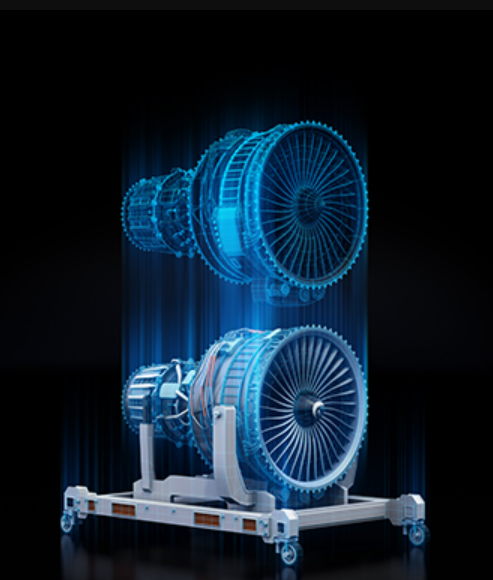

A digital twin is a virtual replica of a physical object or system. The benefits of using digital twins include improved safety, increased efficiency, and reduced costs. For example, digital twins can be used to monitor the performance of a plant or machine in real-time, identify potential issues, and predict potential failures. Additionally, digital twins can be used to create virtual prototypes of products or processes, which can help to reduce development time and costs. Here is a picture depicting a virtual replica of a machine.

Some examples of digital twins include:

- A digital twin of an airplane can be used to monitor its performance and identify potential issues.

- A digital twin of a power plant can be used to monitor its performance and identify potential issues.

- A digital twin of a car can be used to monitor its performance and identify potential issues.

- A digital twin of a person can be used to monitor their health and identify potential issues.

Different types of digital twins and their benefits

There are various different types of digital twins such as component, asset, system and process twins.

- Component twins are created for individual components of a system, such as a sensor or actuator. They can be understood as digital replicas of individual components or sub-systems within a larger system. Component twins are the most elementary form of digital twins. They can be used to simulate the behavior of the component, and to test how changes to the component would affect the rest of the system.

- Asset twins are digital replicas of physical assets, such as machines or vehicles. Asset twins can be used to track the location and condition of the asset, and to predict when maintenance will be required. Asset twins are made of component twins and they are used to monitor the behavior of component twins.

- System twins monitor the behavior of complex systems, such as power grids or transportation networks. System twins are primarily made up of asset twins and they are used to monitor the behavior of asset twins.

- Process twins are digital replicas of business processes, such as the process of manufacturing a product. Process twins can be used to optimize the process, and to identify bottlenecks or other issues. They simulate process flows, such as the movement of people or goods through a facility. Process twins are primarily made up of system twins and they are used to monitor the behavior of system twins.

How businesses are using digital twins

Digital twins are becoming an important part of Industry 4.0 and the Internet of Things (IoT). They allow companies to improve product quality, optimize operations and reduce costs. The following are some of the examples citing businesses which are leveraging digital twins:

- Airbus uses digital twins to monitor the health of its aircraft engines in real time. This helps them to identify potential problems early and take preventative action.

- General Electric is using digital twins to monitor the performance of its gas turbines. This helps them to identify potential issues and optimize operations.

- Ford Motor Company is using digital twins to model the behavior of its vehicles in order to improve product quality and safety.

- Siemens is using digital twins to model the behavior of its manufacturing processes in order to improve efficiency and reduce costs.

Are digital twins and simulations one and same?

Digital twins and simulations might sound like they’re two names for the same thing. After all, they both involve creating a virtual model of something. They may both involve digital representations of physical systems, but they are two very different things. There are some important distinctions between the two. Digital twins are designed to be an exact replica of a physical object, system, or process. This replica is created using data collected from sensors that are attached to the physical object. In contrast, simulations are not necessarily meant to be an accurate representation of reality. Instead, they allow users to test different scenarios and explore different possibilities. Simulations are simplified models that are used to test hypotheses or predict outcomes.

Digital twins can be used for a variety of purposes, from monitoring and diagnostics to control and optimization. Simulations, on the other hand, are typically used for experimentation and analysis, training or risk assessment.

Data Analytics & Digital Twins

Digital twins are often used in conjunction with data analytics, as the data collected by digital twins can be used to improve the accuracy of predictions made by analytics software. The use of digital twins also allows companies to conduct “what if” analyses, which can help them to identify potential problems and solutions.

One of the most important benefits of digital twins is that they can be used to improve the accuracy of predictions made by analytics software. The data collected by digital twins can be used to train predictive models, which in turn can be used to make more accurate predictions about the behaviour of systems and processes.

Future of Digital Twins

As digital twin technology continues to evolve, we can expect more businesses to adopt it in order to improve their operations. Some potential applications for digital twins include:

- Monitoring the health of physical assets

- Improving product quality

- Optimizing operations

- Reducing costs

- Preventing failures

- Enhancing safety

- Managing risks

- Planning for maintenance and repairs

- Scheduling downtime

- Experimenting with new designs.

Digital twins are still in their early stages of development and there is much room for improvement. The accuracy of digital twins will continue to increase as sensor technology improves and more data is collected. In addition, the use of AI and machine learning will allow digital twins to become more autonomous and effective over time. As digital twin technology matures, we can expect to see it become an increasingly important part of Industry 4.0 and the Internet of Things. What do you think? What are some potential applications for digital twins that you can think of? Let us know in the comments below.

Conclusion

Digital twins are becoming an important part of Industry 4.0 and the Internet of Things (IoT). They allow companies to improve product quality, optimize operations and reduce costs. Digital twins are of various different types such as component twins, asset twins, system twins and process twins. Airbus uses digital twins to monitor the health of its aircraft engines in real time. This helps them to identify potential problems early and take preventative action. General Electric is using digital twins to monitor the performance of its gas turbines. This helps them to identify potential issues and optimize operations. Ford Motor Company is using digital twins to model the behavior of its vehicles in order to improve product quality and safety. Siemens is using digital twins to model the behavior of its manufacturing processes in order to improve efficiency and reduce costs. Are digital twins and simulations one and same? Digital twins and simulations might sound like they’re two names for the same thing. After all, they both involve creating a virtual model of something But there are some important distinctions between the two types-digital twin being an accurate replica created with data collected from sensors attached onto physical objects while simulations are simplified models used primarily for experimentation & analysis .

- The Watermelon Effect: When Green Metrics Lie - January 25, 2026

- Coefficient of Variation in Regression Modelling: Example - November 9, 2025

- Chunking Strategies for RAG with Examples - November 2, 2025

I found it very helpful. However the differences are not too understandable for me